In the field of industrial automation, the integration of robotic arms has been viewed as an transforming force, changing the manufacturing landscape and manufacturing processes. Robotic arms, referred to as Arm robots industrial, are now indispensable tools that offer unparalleled quality, safety, and efficiency across many industries. This article examines the diverse potentialities of robotic arms, as well as their effect on the business environment in Australia.

Robotic arm, also referred to as robot arms are versatile mechanical devices designed to mimic human arms’ functionality but with greater precision and endurance. These automated solutions are used extensively in various industries, including electronic assembly and manufacturing for automobiles. Pharmaceutical companies also utilize these devices due to their precision. Robotic arms are programmeable, permitting seamless integration into different manufacturing settings. They are able to provide a dynamic flexibility and can be adapted to changing operating requirements.

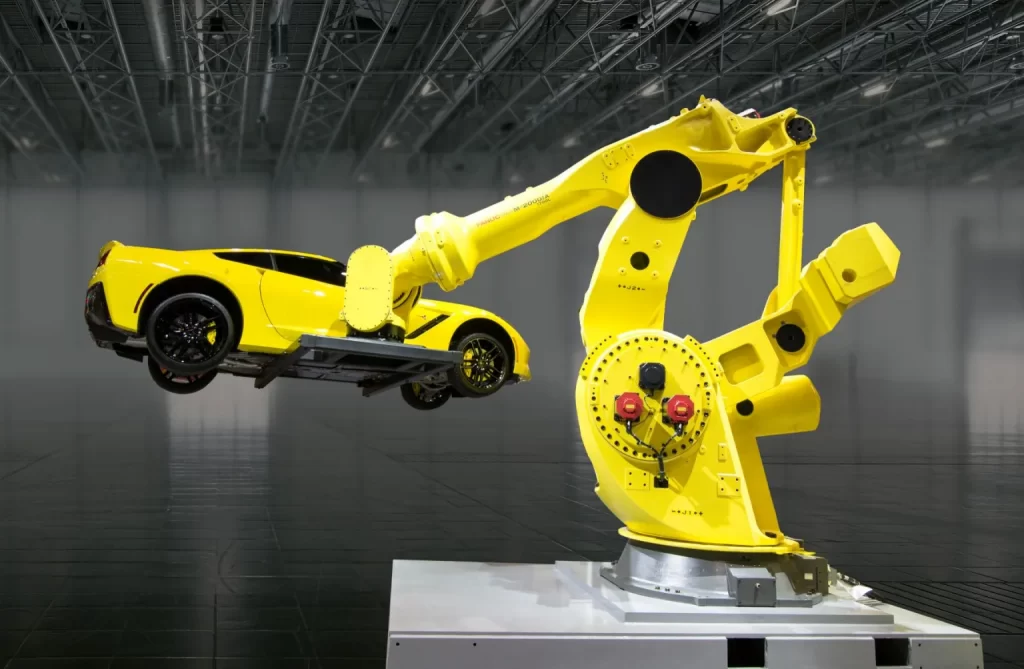

The robotic arm an essential component of modern automation, is an intricate system of joints that can turn and carry out linear displacements. The robotic arm can navigate complex spatial arrangements, manipulate objects with incredible precision, and ensure the safety of human operators. In the end, many industries have embraced robotic arms as essential assets that streamline production processes, elevating operational efficiency to unprecedented levels.

The usage of end-effectors by robotic arms, which are the functional equivalents to human hands, is among their most distinctive features. End effectors are typically created for specific tasks and play an important function in determining the tasks that robotic arms can do. Robots with end effectors specifically designed to perform specific tasks, can accomplish a variety of tasks. From lifting and gripping heavy objects to carefully assembling intricate parts, robotic arms with end effectors that are specifically designed can perform these tasks with unprecedented accuracy and dependability.

The introduction of robotic arms in industrial automation has brought about a new age of productivity and innovation. Robotic arms can help companies enhance their manufacturing processes to reduce human error and improve the quality of their products. The seamless integration between robot arms and automated systems have brought about significant advancements in efficiency. Click here Robotic Arm

Robotic arms create a transformative effect that goes far beyond the automation. They fundamentally alter manufacturing processes. Industrial robotic arms have not only optimized existing manufacturing workflows but has also opened the way for development completely new production methods. With their ability to perform tasks in dangerous or difficult environments, robotic arms have enhanced workplace safety while unlocking new opportunities for complex manufacturing operations.

Further, the growth of robotic arm technology has led to the emergence of innovative end effectors, made to address specific industrial needs. These advanced end effectors, fitted with cutting-edge sensor and gripping capabilities, have widened the scope of applications for robotic arms, which allows firms to meet a range of manufacturing issues with unprecedented flexibility and precision.

Australia is now embracing the potential for automation of robotic arms. Businesses have an opportunity to enhance their competitiveness and operational capabilities. Integration of robotic arms in industrial workflows will drive sustainable growth, improve overall productivity and revolutionize manufacturing. Robotic arms, which are made with precision and efficiency in mind, will allow new opportunities for industrial automation. Companies can reach unprecedented levels of efficiency and productivity.

In conclusion, the introduction of robotic arms, also known as industrial robotic arms, represents a pivotal advancement in the advancement of industrial automation. With their unmatched accuracy, flexibility and safety capabilities robotic arms have reshaped the capabilities of modern manufacturing, giving businesses a competitive edge in a market that is becoming increasingly competitive. As Australia embraces the potential of transformation of robotic arm technology companies stand to profit from improved productivity, operational efficiency, and innovation, underlining the pivotal role of robotic arms in shaping the future of automation in the industrial sector.